Resistive Touch Screen-The Ultimate Guide

INTRODUCTION

What is a Resistive Touchscreen?

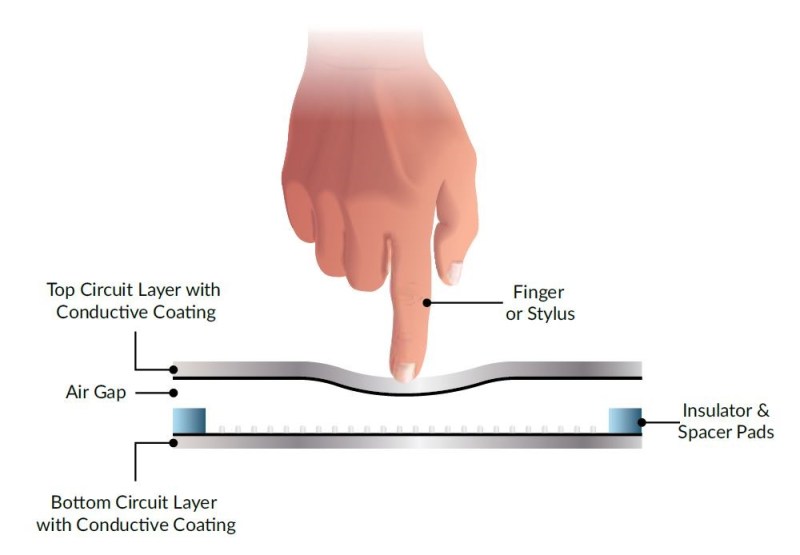

A resistive touchscreen, to put it simply, is a touchscreen that reacts by exerting pressure. It is constructed from two transparent sheets with resistive coatings that are spaced apart by a tiny air gap. These two sheets are pushed together when something touches the touchscreen’s surface. Vertical and horizontal lines on each sheet track the precise place of the contact. Resistive touchscreens are a sort of passive technology since they detect input from contact with almost any item (finger, stylus/pen, palm, etc.).

Touch screens with resistance have a long lifespan. The majority of their applications are in production, ATMs, kiosks, and medical devices owing to this. Please be advised that many industrial settings need to wear gloves while using touch displays. As they don’t require contact with exposed human skin or a pen with capacitive characteristics to function, resistive touch displays are a great fit for this requirement compared to capacitive touch screens, another common technology.

Pros and cons of a resistive touchscreen

Pros:

Excellent resistance and durability are offered by these screens, however, keep in mind that since synthetic materials were utilised to make resistive touch screens, their surface is more prone to wear or scratches. Additionally, due to their sturdy design, the screen can survive dampness and tension without breaking.

People think that resistive touch screens are less sensitive to touch but this is not true. Though these screens recognise physical pressure as a touch, they are quite sensitive as well. Any item that can exert force on the screen may be utilised to achieve the same outcome. Resistive touch displays, for instance, provide dependable single-touch capability in situations where end users wear gloves. Also, because you exert pressure on the screen, they are ideal for locations where minor liquid spills and splatters might accidentally trigger an unintended response from the touch screen. Because of this, industrial settings frequently employ resistive touch panels.

Another main advantage of the resistive touchscreen is its strong anti-interference. Anti-interference in electronics is meant to lessen radio signals’ electronic interference. Thus, this feature acts as a big advantage to industries and that is why resistive touchscreens are utilised mainly for industrial use.

Cons:

Talking about the disadvantages of the resistive touchscreen. Firstly, these touchscreens are equipped with an ITO surface, it is a ternary compound made up of different amounts of the elements indium, tin, and oxygen. ITO is made of ceramic, which makes it fragile and vulnerable to breaking when pressed. And, since ITO film covers their surface, resistive touch screens are more susceptible to scratches or even breaking sometimes.

Secondly, these touchscreens don’t have as excellent transparency as capacitive touch screens. These touchscreens have less transparency. Compared to resistive touch screens, which have more reflections because of their layer count, capacitive screens provide your screen with more vibrancy and clarity.

Lastly, the resolution; both forms of touchscreen technologies have equivalent pixel resolutions. Both, capacitive and resistive touchscreens are frequently able to display even the smallest details because of their excellent picture quality; only LCDs have a different resolution; still, LCDs have the same 4096*4096 resolution.

Why Resistive Touch Screens are popularly used in Industrial Applications?

The majority of industries rely on resistive touch screens out of all the choices available for streamlining procedures and increasing efficiency. The resistive touch is used or is prominent in the industries for the reasons that are listed below:

- The finest feature of resistive touchscreens is that anything pushing on the sensor’s surface will detect a touch because they are pressure sensitive. The additional benefit of being able to employ any stylus tool is helpful for applications that need a very precise touch and for which a fingertip would be too large. In particular, this is valid for compact touchscreens. Additionally, employees in industrial environments frequently wear protective gloves on their hands. With the help of resistive sensors, you can operate the screen while wearing thick gloves.

- Resistive touch screens are mechanically activated, thus even if there are liquids or other objects on the surface, they continue to work as intended. They are therefore particularly helpful in circumstances where chemicals could impair the operation of other types of touch displays. For instance, single-touch applications for boats, underwater machines, and agricultural equipment.

- A prominent reason why OEMs and industries use resistive touch screens is pricing, in addition to their functional advantages. Companies might utilise this option to gain savings that would not be attainable with alternatives in projects where cost is a high priority.

HOW Does a RESISTIVE TOUCHSCREEN WORK?

Two sheets usually referred to as layers, formed of an electrically resistive substance are used in resistive touch controls. An air or inert gas layer separates these layers. The contact between the two layers that make up a resistive touchscreen when you tap it allows it to recognise exactly where you touched.

Electrodes that may be arranged in various ways are present in the two layers of a resistive touchscreen. These electrodes must make contact for a touch command to be sent, regardless of their arrangement.

The two most typical ones are as follows:

The electrodes are arranged in a striped design on the opposing surfaces of the two layers in a matrix configuration, also known as a digital configuration. By putting pressure on the touch panel, it responds to the pressure. It may be controlled by touching it with a stylus, finger, or even a fingernail.

In an analogue design, the electrodes are distributed randomly and on the opposing sides of the layers. Keep in mind that this touch screen may provide greater resolutions and is intended for pen recognition applications.

Types OF RESISTIVE TOUCHSCREEN – explained

- Digital

The X-Y matrix is the basis for this kind of touch screen. To create rows on one layer and columns on the opposite layer, the ITO coating is etched (or deposited selectively). The rows and columns come together to create a matrix of switches. The size of each switch cannot alter; they are all fixed discrete switch locations. The number of rows and columns affects the resolution. Digital touch screens are preferred when finger-sized touch zones are needed since they are as simple to use as a traditional membrane switch keyboard.

- Analogue

When a far better resolution of switches is needed than is feasible with digital architecture, an analogue touch screen is a structure utilised on pen recognition type computers. The lit panel beneath the touchscreen is the only thing stopping the analogue touchscreen’s resolution from easily reaching 1400 dpi or higher. In addition, a 4- or 5-pin connection will do, but a digital device needs a pin for each row and column. The X (or Y) axis is carried by the analogue membrane layer, while the opposing axis is carried by the static (or non-flexing) layer. Different types of analogue screens as are follows:

- 4-wire analogue – In this configuration, there are two electrodes in both the top and bottom layers that are parallel to one another. The positive and negative X-axis are created by the electrodes on the bottom sheet, while the positive and negative Y-axis is formed by the electrodes on the top sheet. The gadget can sense the coordinates where once these two layers come into touch because of this electrical-coordinate configuration.

- 5-wire analogue – Four electrodes are positioned at each corner of the bottom layer in a 5-wire analogue configuration. These electrodes are linked together by four cables. The “sensing wire,” which is incorporated into the top layer, is the fifth wire. The two layers of a five-wire analogue resistive touch screen are most frequently ITO glass on the bottom layer and ITO film on the top layer. The top layer of the five-wire analogue resistive touch screen includes the fifth wire and makes contact with the bottom layer when pressed. The bottom layer of the screen comprises four electrodes connected by four different wires.

A COMPARISON BETWEEN RESISTIVE TOUCHSCREEN AND CAPACITIVE TOUCHSCREEN

Capacitive touchscreens, as opposed to resistive touchscreens, take input from the electrical characteristics of the user’s body. A little electrical charge is attracted to the point of contact when a finger is placed there, allowing the display to identify the input source. The result is a display that can recognise lighter touches more precisely than a resistive touch screen.

PCAP touch panels, in contrast to resistive touch screens, function as a result of changes in an electrical field. A non-conductive object like a pencil cannot activate this screen; only a passive stylus can.

As discussed above resistive touch screens are made of ITO glass and ITO film instead of glass-to-glass as they were in the past. The ITO glass is expensive, which makes resistive touchscreens more expensive than capacitive touchscreens nowadays. ITO film is also significantly more costly than glass, it is highly expensive due to the indium element, and some studies have revealed that ITO-coated glass substrate is the costliest part of device production. So, we can say, unlike earlier times resistive touchscreens are not cheap rather it is expensive.

When we are comparing resistive and capacitive displays, they are simply two types of screens that are utilised for different purposes. Both screens are used for a specific purpose as per one’s requirements and needs. The major point of contention between them might not be price. We can say that resistive touch screens are more appropriate for industrial use because they have more powerful anti-interference. As we previously discussed, having strong anti-interference is one of the main benefits of resistive touch screens for industrial purposes.

On the other hand, Capacitive touch screens are more popular because they support multi-touch and can be made in very large sizes. Nowadays, capacitive touchscreens are more prevalent mostly in consumer goods like smartphones or tablets. Nevertheless, there are several benefits to using a resistive touch screen. Only touchscreens with resistive technology can recognise a touch command from a user who is using a conventional stylus. For usage with capacitive touch displays, where users must use an exposed finger or a specialised capacitive stylus, the majority of regular styluses are non-conductive.

The specific requirements of your application will determine whether to employ a capacitive or resistive touchscreen.

Considerations while selecting a resistive touchscreen

- Talking about the most popular resistive touchscreen options to choose from, there are two currently, the 4-wire and 5-wire. Both of these resistive touch displays are capable of detecting your touch instructions and responding to them. The difference between both types of screens is the price, usually, the 4-wire is the cheaper one.

- The substance a resistive touchscreen is constructed of is a critical additional consideration. Examine the substance utilized in the touch panel’s various layers in particular.

- Get a resistive touch solution with strong resistance to moisture, dust, and other pollutants if you need it for outdoor or severe applications.

CONCLUSION

Resistive touchscreen technology offers both benefits and drawbacks, similar to other touchscreen technologies. They support all types of touch instructions and are sturdy and powerful. The best touchscreen for an industrial application today is the resistive touch screen, despite its high cost. These screens provide exceptional durability and resistance. When compared to capacitive displays, we can state that each screen has distinct market popularity and function. Choosing the touchscreen is dependent on the fact that what is the purpose of its utilisation.

We hope the blog “Resistive Touchscreen – The Ultimate Guide”, has been able to provide you with reliable information regarding resistive touchscreen technology. The goal of this guide is to provide you with as much assistance and knowledge as possible.

from

https://eagle-touch.com/resistive-touchscreen-the-ultimate-guide/

Article Source : eagletouch1.weebly.com/blog...